Thread Starter

#16

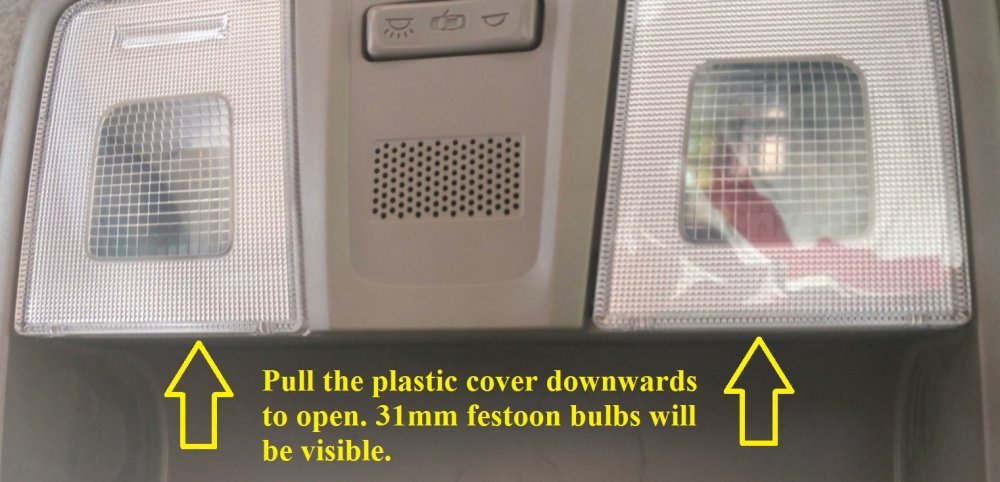

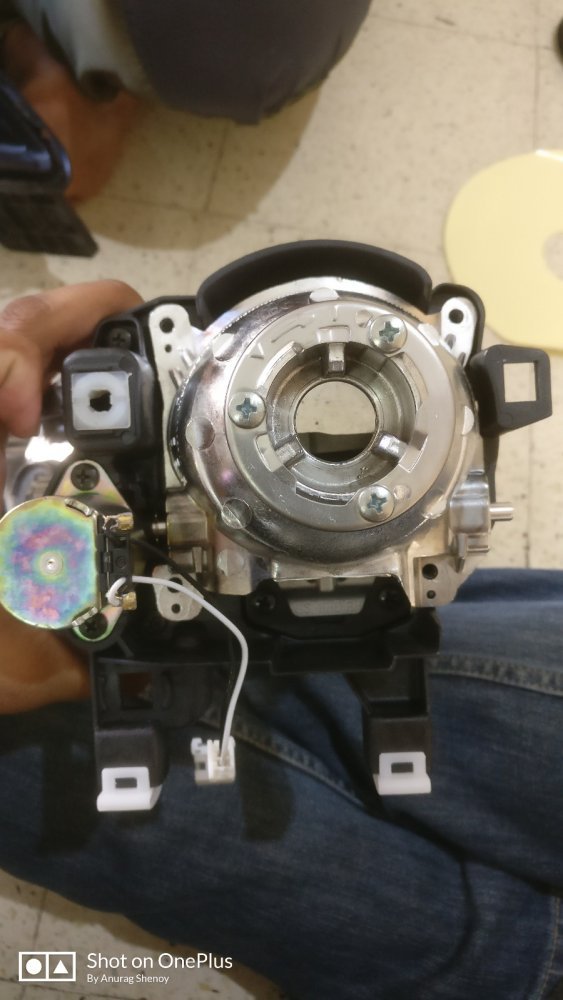

Power Window switch illumination

Power window switches from AliExpress

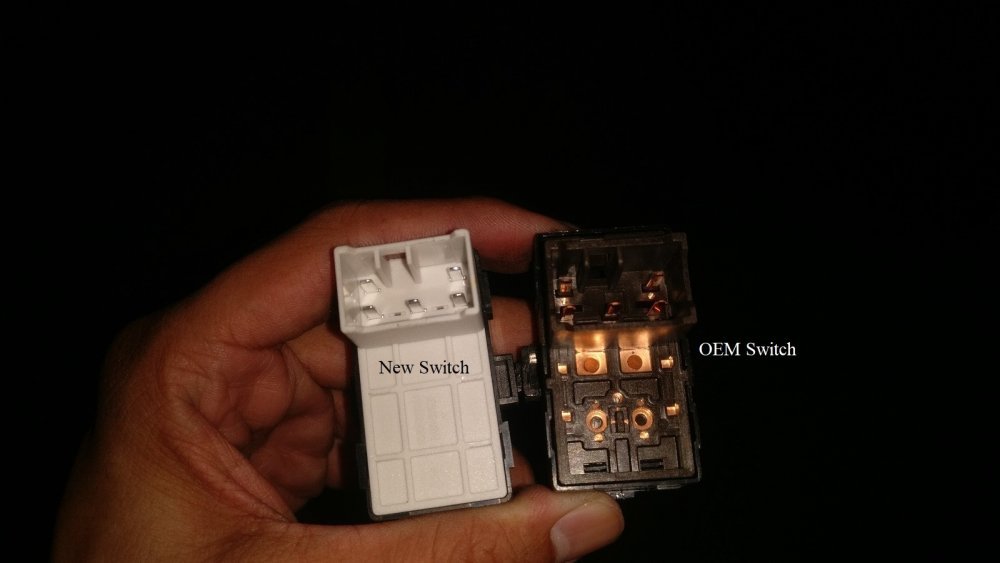

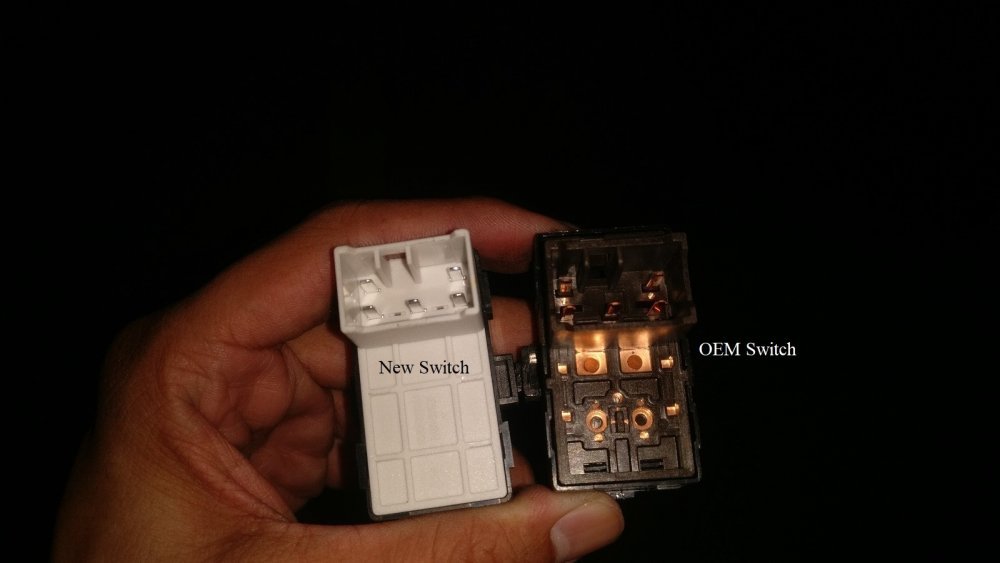

New vs OEM switch

Door pad removed

The power window connector removed

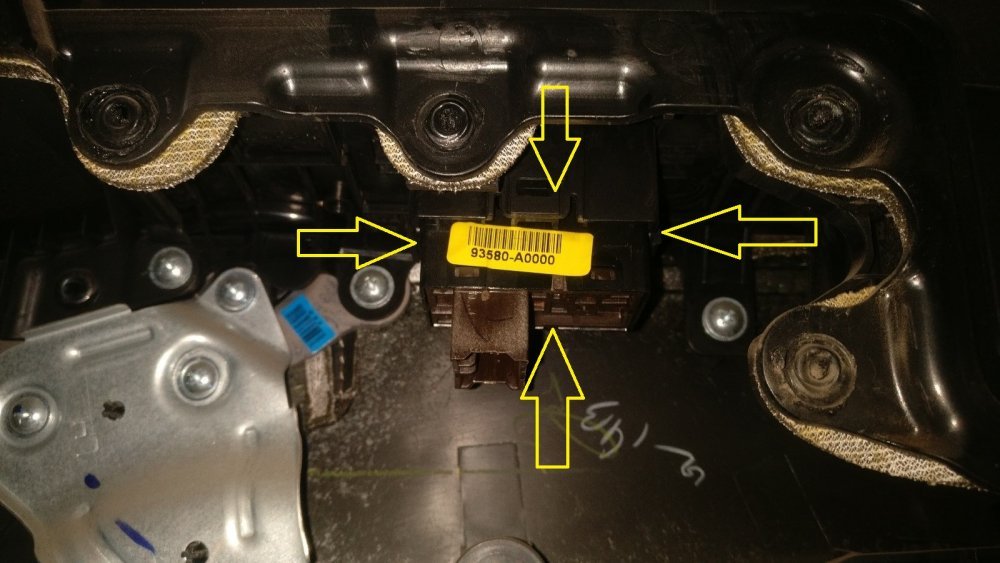

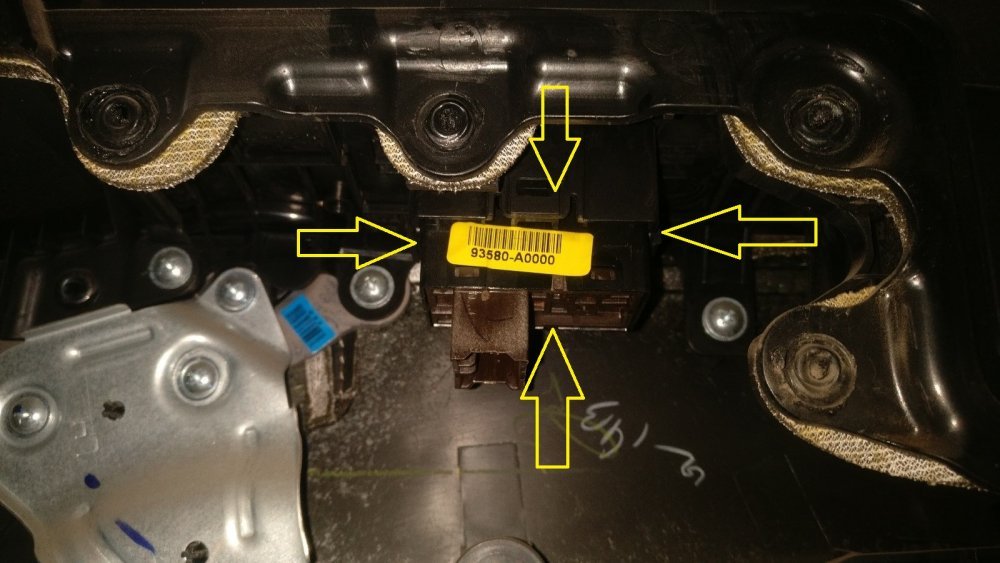

Using a small flat screwdriver, pry the tabs (marked using the arrows in yellow) to free the switch from the door pad

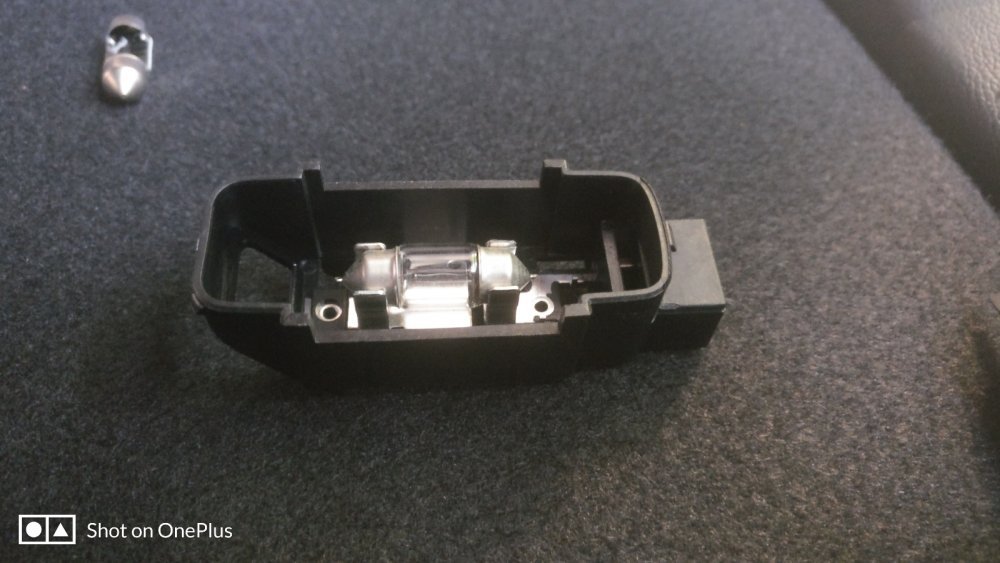

The power window switch removed

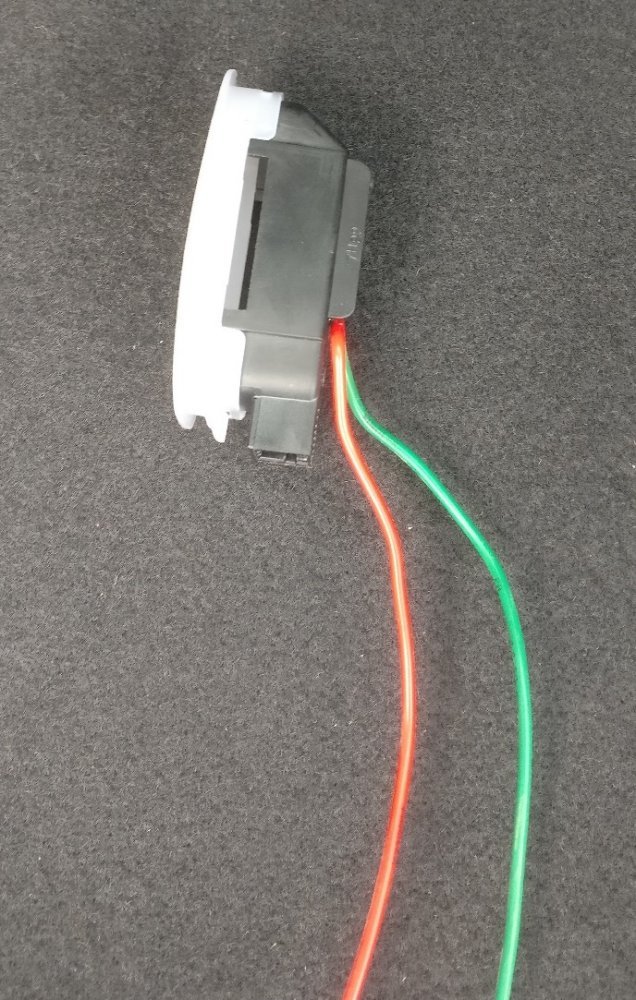

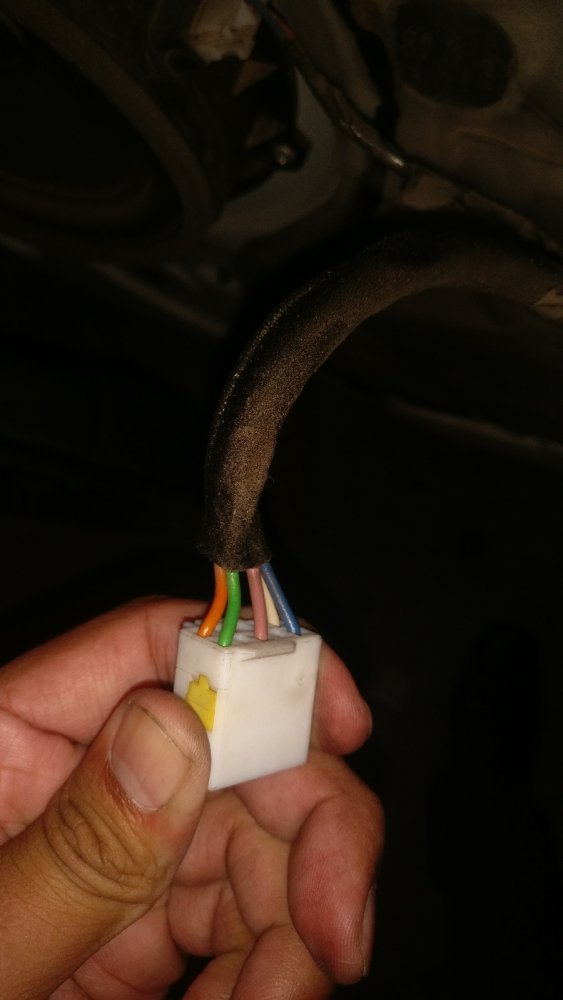

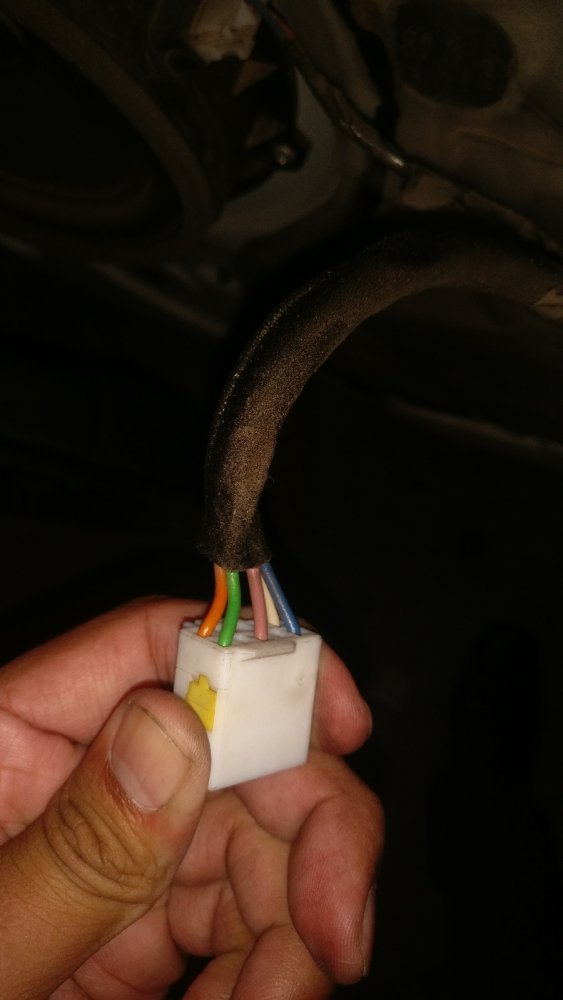

The 5-pin power window switch connector

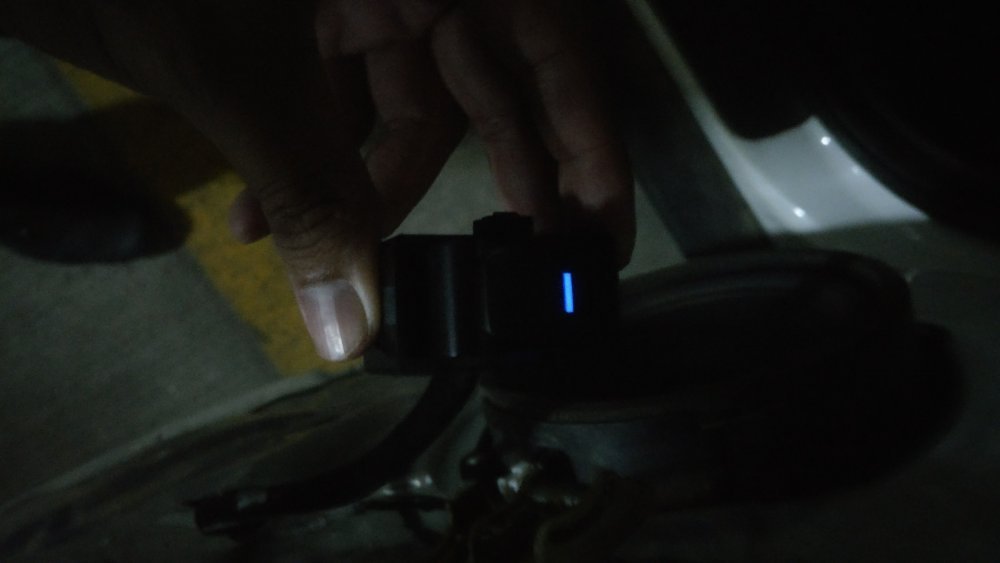

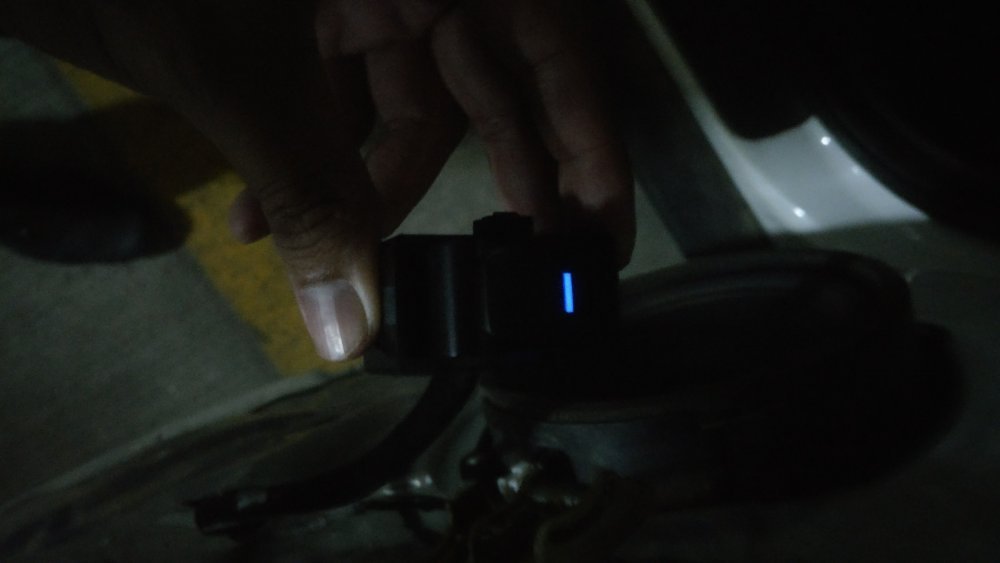

Test successful

Rear switch installed

Front switch installed

Close-up of the illumination

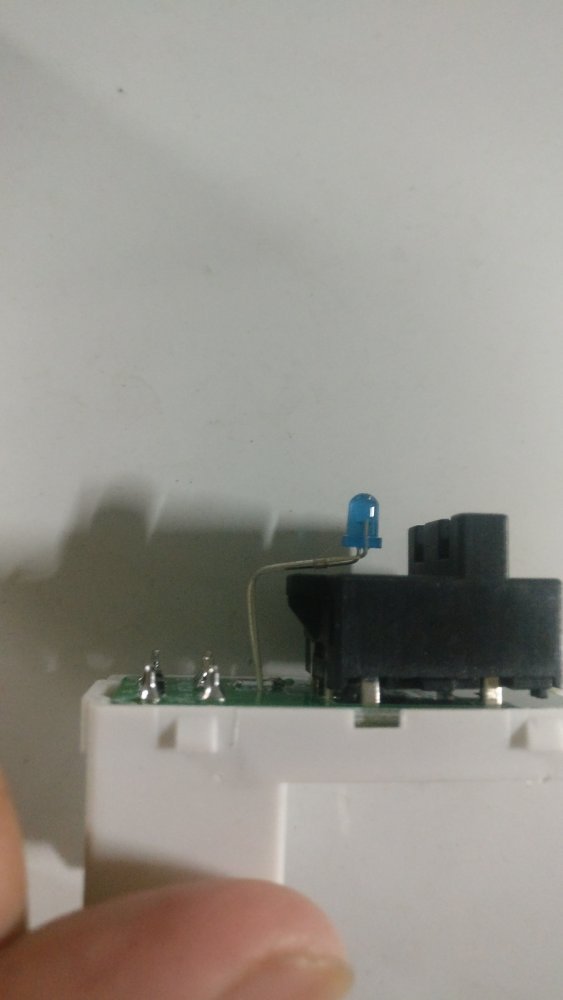

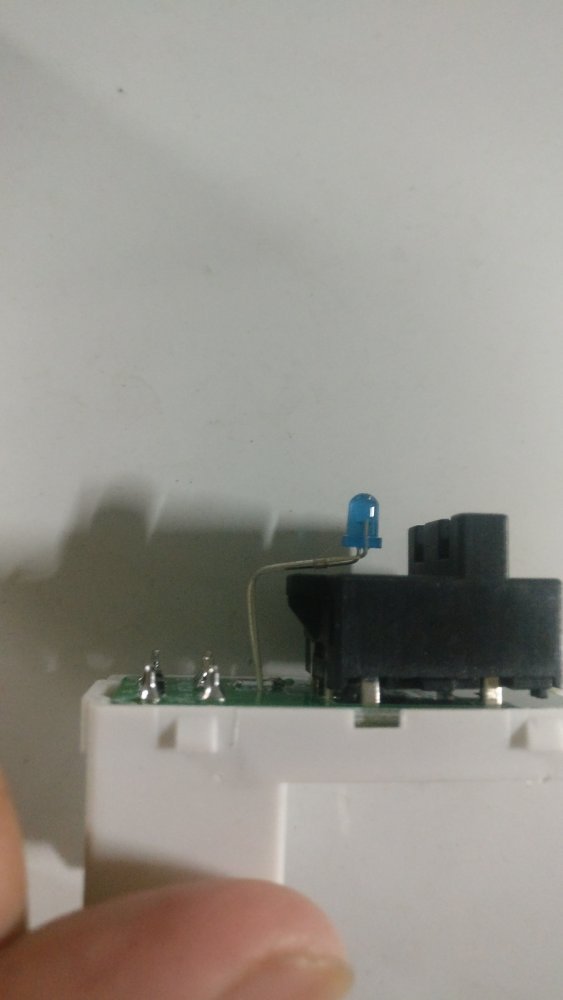

Small LED bulb for the illumination - matches the interior lighting

- Hyundai India conveniently decided to omit the lighting on the individual power window switches making it difficult for users to locate the switch during night times. Thanks to AliExpress, these switches were readily available at a decent price. Without much thought, I went ahead and got three of them.

Power window switches from AliExpress

New vs OEM switch

Door pad removed

The power window connector removed

Using a small flat screwdriver, pry the tabs (marked using the arrows in yellow) to free the switch from the door pad

The power window switch removed

The 5-pin power window switch connector

Test successful

Rear switch installed

Front switch installed

Close-up of the illumination

Small LED bulb for the illumination - matches the interior lighting

- The point here is, the wiring etc is ready in the car with this feature enabled but Hyundai decided to cheap out on the switches and all it takes is a simple switch change to get this lighting to work. This modification is not going to make any 'real' difference in operation but will address something that should have been there since day 1.

Last edited: