Thread Starter

#16

.

Excellent article and efforts CRACING!

This one about car polishers, I wanted to do some research and write something after on my personal use and observations. I would give this link in our thread: http://www.theautomotiveindia.com/f...83-exhaustive-guide-car-detailing-basics.html

Excellent article and efforts CRACING!

This one about car polishers, I wanted to do some research and write something after on my personal use and observations. I would give this link in our thread: http://www.theautomotiveindia.com/f...83-exhaustive-guide-car-detailing-basics.html

Thank you for your appreciations. I still don't believe I made this article but this car detailing topic is too vast so I was not able to provide complete details. However, there is no end for it and different people opt different ways that suits them better.

i.e DA or Orbital polisher costs 3 to 4 times of a rotary polisher so not everybody can afford it. Experts advice DA or Orbital polisher because its safe on paint and easy to handle but if one has confidence and do some practices, rotary polisher can be a best car polisher. Of course, rotary polisher is no good for most of wax applications because its too fast but for that we can opt hand application. On the other hand, I have read plenty of rotary polisher users using it without any issues and some don't even like DA or Orbital polisher. Its just a personal preference.

1. You have quoted But, I find it one B&D model is available @Rs.3500/- in India (KP1200 Car Polisher). It has different handle, Disc Diameter10" but no speed regulator. What is your opinion? Shall we go for the 6” model Black n Decker KP600 60W?

1. Its not so powerful for polishing. No Load Speed of 3200 rpm will drop when pressed on surface because of low wattage (i.e 120w).

2. The backing plate is non removable and 10 inch would be too big when working on small portions or panels.

3. AFAIK, the inter foam pad is not usable. User has to fit bonnet on it for polishing/waxing. Also 10" bonnets are not easily available in India.

4. Wool bonnet that comes with it can make swirls so not recommended. Even on Rotary, DA, Orbital Polishers. Read below for more info.

5. It has no speed control and runs at 3200 RPM at no load. No good because wax application should be done under 600 RPM speed for perfect bonding.

Wool bonnet is used for paint removal/corrections because its most aggressive. Once finished, we have to use different dense foam pads for removal of micro fine swirls. Process is just like we use sand papers. i.e 400 -> 2000 -> 4000 -> 6000 Grit.

p.s My neighbor had bought same machine two years ago but was not satisfied. It hops a lot or reduces speed if pressed hard. Newer cars have curved surfaces so large backing plate is also the reason for hop. I saw them using once and never again.

B&D KP600 is not available in India and also I cannot find its spec in official B&D websites, including international. From international sales websites (Link), it seems a Random Orbit Waxer/Polisher which is a good thing but I doubt 60w would be sufficient. No speed control is also a problem. May be its better alternative to manual process and pricing is also good.

2. You have put the pictures of Skil 9080 Car Polisher parts. Please tag/identify the name of parts so that anybody can understand what are what and understand the use and explanation from your beautiful article.

1. Polisher aka Machine Unit. It weights 3.5 KG excluding cable so little heavy to handle.

2. One that looks like D is called D Handle. (For me it looks like G though) It has to be attached to the polisher/machine with two screws provided and allen key to tight it.

3. Alternatively, there is also Auxiliary handle provided that attaches to polisher/machine. You can use either D handle or Auxiliary handle. Which ever you feel better to hold the polisher.

4. One that looks like plate, a nut in the center and yellow color band round it, is called Backing plate. It has dia of size 7", nut aka spindle size is M14 (14mm approx) and Velcro aka Hook & Loop in the other side of the plate. Yellow colored hard foam is also sandwiched in-between.

5. Orange color waffle pad is provided for wax/polish application and it attaches to backing plate using Velcro aka Hook & loop thing. Size is 7" so you have be careful in corners/edges and do let backing plate to touch anything.

6. Finally user manual is provided and a booklet for Skil/Bocsh service center locations.

3. I understand different pads are used for different purpose -Ultra-Light Finishing – Finishing -Light Polishing/Finishing - Light-Medium Polishing- Heavy Polishing- Medium-Heavy Cutting- Heavy Cutting. Is Foam sponge OK up to Light-Medium Polishing?

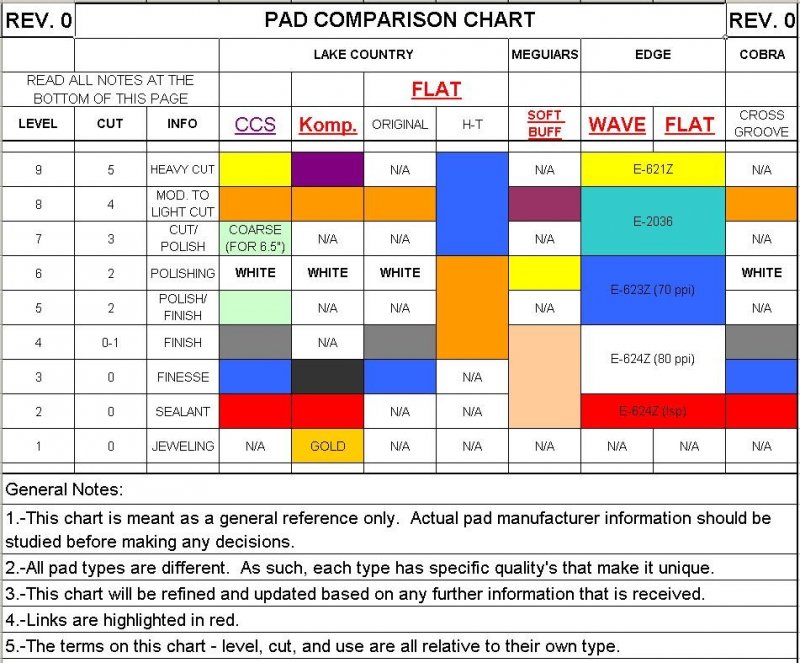

Here is chart that has details of different pads from different brands:

There are some laser cut pads like CCS, Waffle, Hex which are made to reduce heat produced when polishing plus some other benefits but I see most don't like it or they are more satisfied with flat pads.

4. What backing plate size you prefer for people like us? Smaller is better? Whether it comes with interchangeable sizes?

Kindly note; Polishing pads should be 0.5 - 2 inch bigger then backing plates so that backing plate doesn't touch the edges or curves of the car body.

Here is a nice guide from Chemical Guys:

https://www.youtube.com/watch?v=CI78DjvsLwA

Few days ago, I had visited to Bosch service center to find Velcro Backing Plates and lucky, I could get one 5" plate. It is not Bosch branded but quality is good and fits well to my Rotary spindle. Cost is Rs. 175. Now I'm looking to buy Lake Country Flat White Polishing Pad for AIO product application but it costs Rs. 850 per pad so I shouldn't make mistake when choosing.

Here are the snaps:

* 7" Backing Plate is the one came with the machine and 5" is the one I bought.

* M10 written in 5" Backing Plate is wrong/typo. Actually its M14.

Similar pad is available in ebay India but cost is Rs. 350. Link The nut doesn't look well molded into the pad and I doubt it holds strong while polishing.

Another one is listed in paytm which costs Rs. 170. Link Overall quality doesn't look good in pictures.

5. Finally , thanks for everything and acknowledging my thread: http://www.theautomotiveindia.com/f...83-exhaustive-guide-car-detailing-basics.html

![Smile [:)] [:)]](https://www.theautomotiveindia.com/forums/images/smilies/Smile.gif)

Last edited:

![Big Smile [:D] [:D]](https://www.theautomotiveindia.com/forums/images/smilies/Big%20Smile.gif) Product used was Rotary Polisher, 5" Backing Plate, Carpro Rayon 5" Glass Polishing Pad, Proklear Pre-Cleaner (It comes with their NSG kit) and plenty of water.

Product used was Rotary Polisher, 5" Backing Plate, Carpro Rayon 5" Glass Polishing Pad, Proklear Pre-Cleaner (It comes with their NSG kit) and plenty of water.