Off Road Buggy - A College Project

- Thread Starter rvndraju

- Start date

Thread Starter

#32

Hello mates i had my 1st internal assessment so was busy studying and we did not work on Monday and Tuesday.

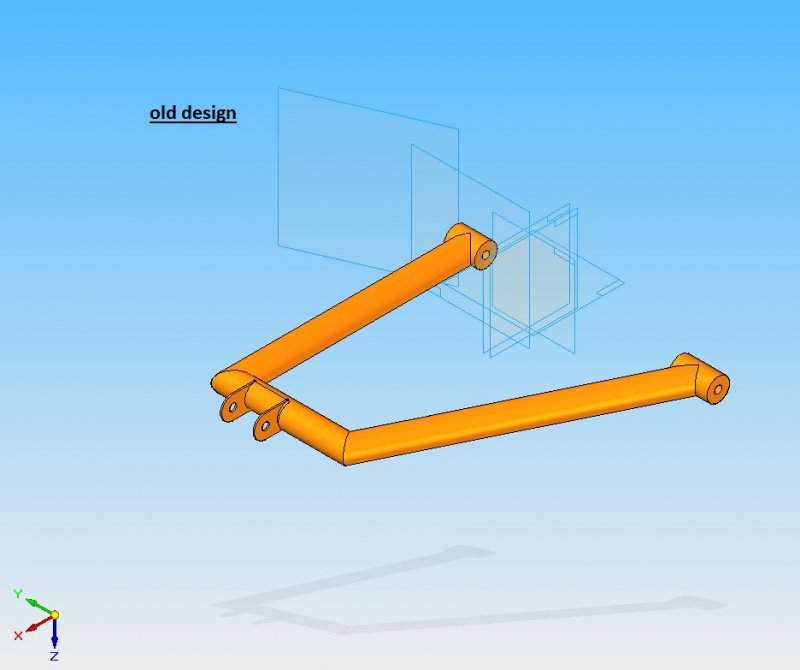

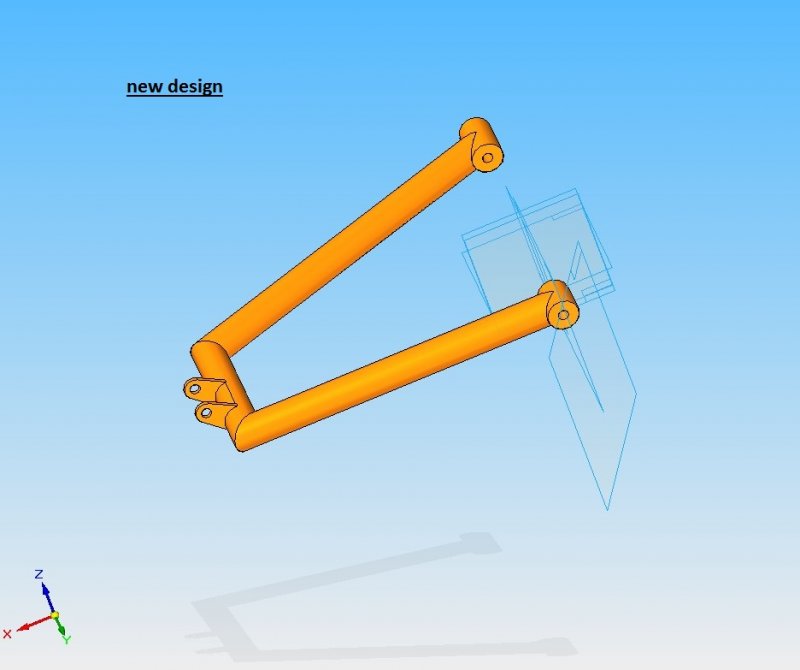

we started off yesterday and till today we completed fabricating the rear control arms, mounts & bushes. Actually we had planned to go for a trailing arm in the rear but in the CAD design we observed that CV shafts where taking too much angles in static conditions which shouldn't happen![Confused [confused] [confused]](https://www.theautomotiveindia.com/forums/images/smilies/Confused.gif) so we decided to go for DOUBLE WISHBONE type. finally we designed a lower H arm & upper I arm setup.

so we decided to go for DOUBLE WISHBONE type. finally we designed a lower H arm & upper I arm setup.

we started off yesterday and till today we completed fabricating the rear control arms, mounts & bushes. Actually we had planned to go for a trailing arm in the rear but in the CAD design we observed that CV shafts where taking too much angles in static conditions which shouldn't happen

![Confused [confused] [confused]](https://www.theautomotiveindia.com/forums/images/smilies/Confused.gif) so we decided to go for DOUBLE WISHBONE type. finally we designed a lower H arm & upper I arm setup.

so we decided to go for DOUBLE WISHBONE type. finally we designed a lower H arm & upper I arm setup.Attachments

-

157.7 KB Views: 434

-

129.6 KB Views: 210

-

140.9 KB Views: 176

-

151.6 KB Views: 188

-

156.9 KB Views: 162

-

181.2 KB Views: 186

-

185.4 KB Views: 187

-

107.7 KB Views: 516

Thread Starter

#33

PrObLeM :(

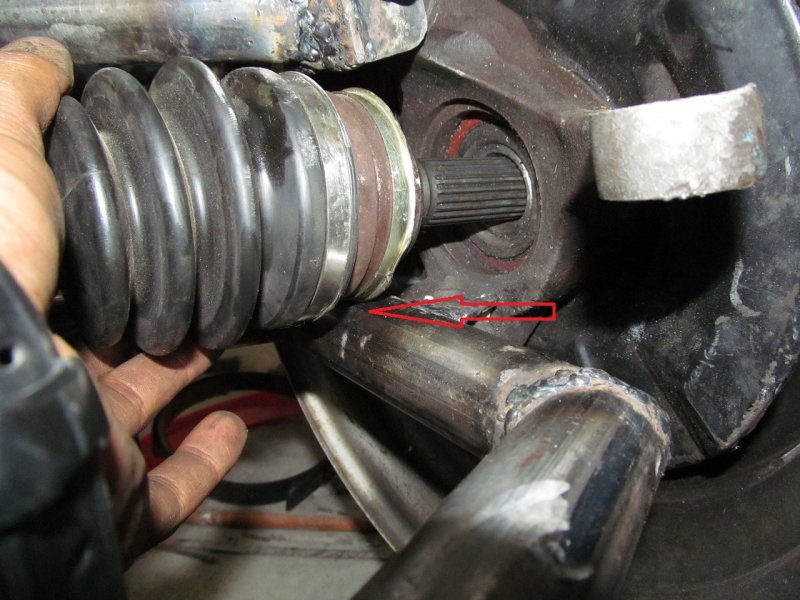

Hello mates we got into a big problem today. we where happy that the rear control arms were completed. After mounting the arms we mounted the CV shaft that is where the Bl***Y problem started. the control arm was obstructing the CV head to get into the wheel hub. . After working so much today we felt so frustrated at the end of the day

. After working so much today we felt so frustrated at the end of the day ![Frustration [frustration] [frustration]](https://www.theautomotiveindia.com/forums/images/smilies/Frustration.gif) .

.

one of my team mate suggested to go for a smaller CV but cant spend $$ again because we have lot more stuffs to buy in our limited budget.

Another team mate suggested that we modify the lower arm such that the lower pivots are raised a couple of cm's buy placing it in a inclined position so that the arm gets lower.

Tomorrow's work is to modify the lower arm and successfully mount the CV's because we are nearing the deadline and goto complete our vehicle soon :(

Hello mates we got into a big problem today. we where happy that the rear control arms were completed. After mounting the arms we mounted the CV shaft that is where the Bl***Y problem started. the control arm was obstructing the CV head to get into the wheel hub.

![Frustration [frustration] [frustration]](https://www.theautomotiveindia.com/forums/images/smilies/Frustration.gif) .

. one of my team mate suggested to go for a smaller CV but cant spend $$ again because we have lot more stuffs to buy in our limited budget.

Another team mate suggested that we modify the lower arm such that the lower pivots are raised a couple of cm's buy placing it in a inclined position so that the arm gets lower.

Tomorrow's work is to modify the lower arm and successfully mount the CV's because we are nearing the deadline and goto complete our vehicle soon :(

Attachments

-

463.4 KB Views: 2,291

-

427.9 KB Views: 212

-

465 KB Views: 211

-

70.8 KB Views: 170

-

72.2 KB Views: 170

-

451.2 KB Views: 243

Thread Starter

#34

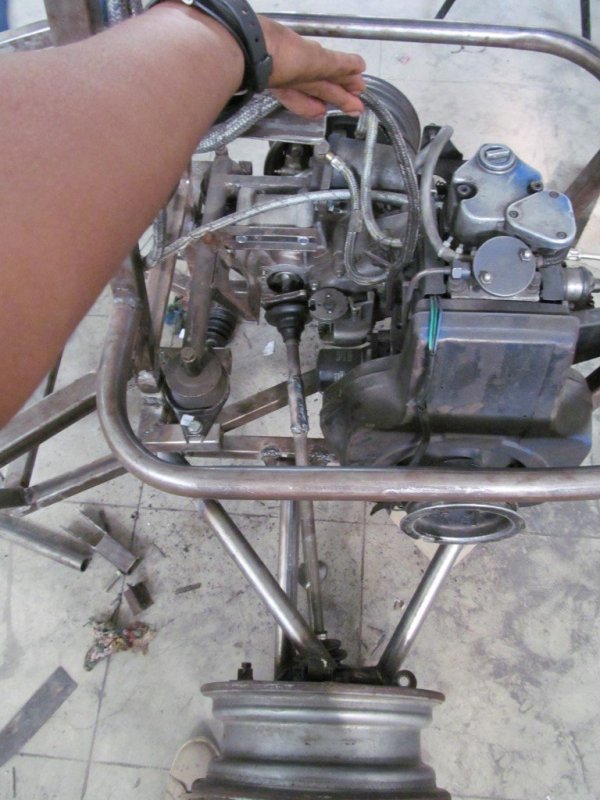

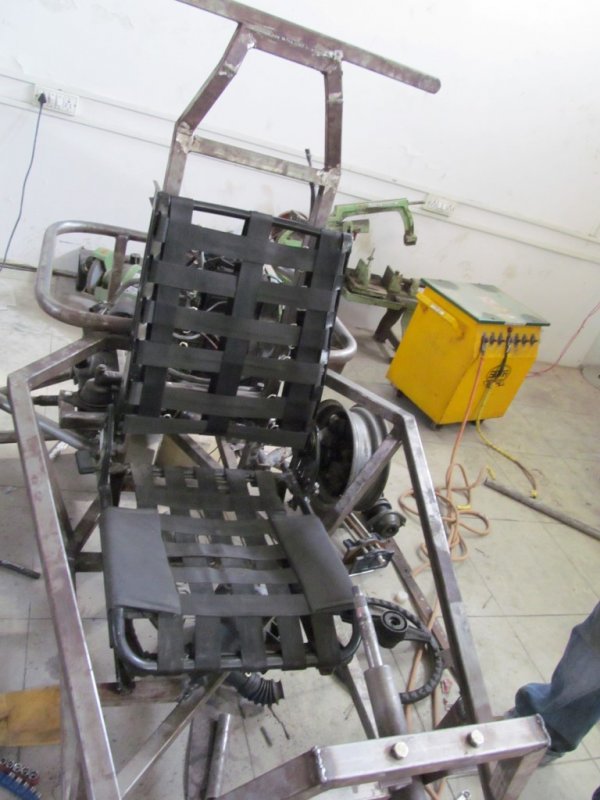

Hi mates i got busy with my seminar presentation so we did not work from past 2 days. But We worked on Tuesday & wednesday and could complete the rear end.

The axles where giving us lot of trouble so we had to work on it a lot and wasted too much time on it. Sines two different axles had to be welded together to suite our requirement it was a time consuming job :( .

The right side axle was too short and more inclined so the axle plunge which we got was too less so it restricted the wheel travel to 100mm :( . But the left side had a good travel because the length of the axle was big and was also less inclined.

After completing the rear end we started of with some body work. Brought a 4ft*8ft GI sheet from a scrap yard near my place it was weighing around 12.5 kg and shop guy charged us Rs. 40/kg. Folded the sheet and carried it to collage in my team mated dio![Big Smile [:D] [:D]](https://www.theautomotiveindia.com/forums/images/smilies/Big%20Smile.gif) .

.

started covering the base and firewall. the sheets will be screwed to the frame. We tried welding it but 50amps current (least in out m/c) was melting of the sheet with just a touch of the torch.

Tomorrow we are heading to Siddaiah Road truck scrap yard to buy seat. We are buying a truck seat actually but it suits best for off-road also.

The axles where giving us lot of trouble so we had to work on it a lot and wasted too much time on it. Sines two different axles had to be welded together to suite our requirement it was a time consuming job :( .

The right side axle was too short and more inclined so the axle plunge which we got was too less so it restricted the wheel travel to 100mm :( . But the left side had a good travel because the length of the axle was big and was also less inclined.

After completing the rear end we started of with some body work. Brought a 4ft*8ft GI sheet from a scrap yard near my place it was weighing around 12.5 kg and shop guy charged us Rs. 40/kg. Folded the sheet and carried it to collage in my team mated dio

![Big Smile [:D] [:D]](https://www.theautomotiveindia.com/forums/images/smilies/Big%20Smile.gif) .

. started covering the base and firewall. the sheets will be screwed to the frame. We tried welding it but 50amps current (least in out m/c) was melting of the sheet with just a touch of the torch.

Tomorrow we are heading to Siddaiah Road truck scrap yard to buy seat. We are buying a truck seat actually but it suits best for off-road also.

Attachments

-

198.5 KB Views: 177

-

171.4 KB Views: 179

-

152.4 KB Views: 168

-

166.2 KB Views: 443

-

192.5 KB Views: 152

-

124.2 KB Views: 184

-

173.6 KB Views: 180

-

150.6 KB Views: 184

-

129.6 KB Views: 164

-

172.5 KB Views: 174

-

187.8 KB Views: 241

You people are really going at a fantastic pace I must say. Its just 4 days back that we also started our college project and just to give ourselves a bigger challenge, we have brought our deadline down from 45 days to 25 days and made the announcement that our vehicle will be moving around on 25th April(this way we will be forced to complete the work any way), bought a Maruti 800(for 15500), dismantled it, sold its engine etc(for 6500) and taken out useful things like steering, brakes, seats, front suspension, all four rims and tyres, wheel hubs etc. Here are a couple of pics of all we did in past 4 days:

Sorry for poor picture quality, wishbones are ready, today we will be framing out our strategy for next 20 days and then will be putting mounting points for various things on our chassis.

Sorry for poor picture quality, wishbones are ready, today we will be framing out our strategy for next 20 days and then will be putting mounting points for various things on our chassis.

Thread Starter

#36

Hi vipul nice to see that you have started the fabrication of the chassis and completed it just in 4 days. I see that you have applied primer (red oxide) to the frame is it okay to apply it before mounting all the components?. because there will be lot of welding work on it while mounting components.

you brought a Maruthi 800 for 15000![Surprise [surprise] [surprise]](https://www.theautomotiveindia.com/forums/images/smilies/Surprise.gif) I really regret now about the M800 components which i brought for our project & for which we paid 11000 :( :( .

I really regret now about the M800 components which i brought for our project & for which we paid 11000 :( :( .

Today is holiday so could not work so we went to buy seat, clutch, throttle, gear cables. paid 1000 for the seat and 600 for all the cables. the seat is actually used in trucks and modified off road jeeps it has a front-back sliding and reclining mechanism the shop guy demanded 1000 extra for mounting height adjustment mechanism but we decided not to wast money for that.

monday we will start mounting the seat and work in mounting the rear shocks

you brought a Maruthi 800 for 15000

![Surprise [surprise] [surprise]](https://www.theautomotiveindia.com/forums/images/smilies/Surprise.gif) I really regret now about the M800 components which i brought for our project & for which we paid 11000 :( :( .

I really regret now about the M800 components which i brought for our project & for which we paid 11000 :( :( . Today is holiday so could not work so we went to buy seat, clutch, throttle, gear cables. paid 1000 for the seat and 600 for all the cables. the seat is actually used in trucks and modified off road jeeps it has a front-back sliding and reclining mechanism the shop guy demanded 1000 extra for mounting height adjustment mechanism but we decided not to wast money for that.

monday we will start mounting the seat and work in mounting the rear shocks

Attachments

-

223 KB Views: 165

-

236.8 KB Views: 148

Last edited:

A couple of things which I feel that you need to look into is your front suspension arms where they are connected to the knuckle using tiero ends I feel that design is too weak also I feel your modifications done on your axle will end up giving you tremendous vibrations.

Thread Starter

#38

Progress after 2 days

Work completed in past 2 days

Work remaining

Work completed in past 2 days

- Seat was mounted.

- The Master cylinder and pedal assembly was mounted

- Finalized the steering column & optimal pedal position.

- The Roll cage was permanently welded to the chassis.

Work remaining

- Mounting front and rear suspension

- Mounting Fuel filter & air filter

- Fixing the base sheet and body work

- Painting

- MOunting tires

- Custom manifolds for dual EXHAUST

- Fixing brake hoses

Attachments

-

182.1 KB Views: 162

-

210.9 KB Views: 147

-

192 KB Views: 144

-

166.8 KB Views: 143

-

152.3 KB Views: 137

-

165.5 KB Views: 131

-

173.7 KB Views: 157

-

128.8 KB Views: 136

-

169.3 KB Views: 152

-

168 KB Views: 144

-

109.5 KB Views: 139

-

151.1 KB Views: 145

-

184.1 KB Views: 136

-

193.2 KB Views: 142

-

172.8 KB Views: 151

Thread Starter

#39

Help required

hi mates we brought Maruthi 800 front coil over shock to use it in our rear suspension. The problem is when the strut was mounted the top mount was too high, like it was above the mounting frame. so we decided to shorten the length of the strut

Any suspension experts please look into this and give some suggestions .

we are planning to shorten the length by cutting off the tube below the spring but i was worried like what if it is the oil reservoir :(

Pictures added for more detail

hi mates we brought Maruthi 800 front coil over shock to use it in our rear suspension. The problem is when the strut was mounted the top mount was too high, like it was above the mounting frame. so we decided to shorten the length of the strut

Any suspension experts please look into this and give some suggestions .

we are planning to shorten the length by cutting off the tube below the spring but i was worried like what if it is the oil reservoir :(

Pictures added for more detail

Attachments

-

210.3 KB Views: 130

-

235.5 KB Views: 137

Last edited:

Re: Help required

Not possible buddy.

It's not just a tube. Strut construction is Outer tube (what you decided to chop), Inner tube and inside this there is a Piston & Piston rod. You can't chop-off everything, which will result in reduction of total stroke and unbalanced Bound & Rebound stroke.

Instead you can try damper from other vehicles.

so we decided to shorten the length of the strut

Any suspension experts please look into this and give some suggestions .

we are planning to shorten the length by cutting off the tube below the spring but i was worried like what if it is the oil reservoir :(

Any suspension experts please look into this and give some suggestions .

we are planning to shorten the length by cutting off the tube below the spring but i was worried like what if it is the oil reservoir :(

It's not just a tube. Strut construction is Outer tube (what you decided to chop), Inner tube and inside this there is a Piston & Piston rod. You can't chop-off everything, which will result in reduction of total stroke and unbalanced Bound & Rebound stroke.

Instead you can try damper from other vehicles.

Thread Starter

#41

Re: Help required

Thank you mate, i am planning to go for a tower setup by retaining the strut as it is.

Not possible buddy.

It's not just a tube. Strut construction is Outer tube (what you decided to chop), Inner tube and inside this there is a Piston & Piston rod. You can't chop-off everything, which will result in reduction of total stroke and unbalanced Bound & Rebound stroke.

Instead you can try damper from other vehicles.

It's not just a tube. Strut construction is Outer tube (what you decided to chop), Inner tube and inside this there is a Piston & Piston rod. You can't chop-off everything, which will result in reduction of total stroke and unbalanced Bound & Rebound stroke.

Instead you can try damper from other vehicles.

Attachments

-

296.1 KB Views: 226

Thread Starter

#42

front shock mount

since it's a bit complicated with the rear shock mount i will start of with it after mounting front shocks which will be completed tomorrow.

after drilling and tapping the holes the base and firewall sheets where screwed to the frame.

since it's a bit complicated with the rear shock mount i will start of with it after mounting front shocks which will be completed tomorrow.

after drilling and tapping the holes the base and firewall sheets where screwed to the frame.

Attachments

-

138.1 KB Views: 143

-

215.7 KB Views: 152

-

212.6 KB Views: 155

-

169.1 KB Views: 136

-

183.4 KB Views: 132

-

168.4 KB Views: 138

-

149.4 KB Views: 140

-

112.6 KB Views: 149

-

137.9 KB Views: 140

@Rvndraju:

Great progress I must say, we are also done with our front suspension and steering. Pics will be coming, we are planning to wrap up by 25th and since our front is nearly done and rear differential mountings are also near ready, so we believe that it will be done on time.

BTW, you coming for BAJA SAEINDIA 2015? Registrations are open and good is that this year even final year students can also participate. I have just 5 minutes back finished the registration of my team.

Great progress I must say, we are also done with our front suspension and steering. Pics will be coming, we are planning to wrap up by 25th and since our front is nearly done and rear differential mountings are also near ready, so we believe that it will be done on time.

BTW, you coming for BAJA SAEINDIA 2015? Registrations are open and good is that this year even final year students can also participate. I have just 5 minutes back finished the registration of my team.

Thread Starter

#45

Great progress I must say, we are also done with our front suspension and steering. Pics will be coming, we are planning to wrap up by 25th and since our front is nearly done and rear differential mountings are also near ready, so we believe that it will be done on time.

BTW, you coming for BAJA SAEINDIA 2015? Registrations are open and good is that this year even final year students can also participate. I have just 5 minutes back finished the registration of my team.

BTW, you coming for BAJA SAEINDIA 2015? Registrations are open and good is that this year even final year students can also participate. I have just 5 minutes back finished the registration of my team.

![Surprise [surprise] [surprise]](https://www.theautomotiveindia.com/forums/images/smilies/Surprise.gif) ?. I guess you will be the team adviser. All the best for your team.

?. I guess you will be the team adviser. All the best for your team. We could't work whole last week because of internals and holidays due to election and stuffs. Till today we could complete the front & rear shock mount, fixing throttle, clutch etc cables. We are also planning to wrap up by 26th if possible.

testing shock

![Big Smile [:D] [:D]](https://www.theautomotiveindia.com/forums/images/smilies/Big%20Smile.gif) https://www.youtube.com/watch?v=CFAeJ7_2K6g

https://www.youtube.com/watch?v=CFAeJ7_2K6gWork remaning:-

- side panels & front panels

- Gear lever assembly

- connecting brake pipes & brake overhaul

- Fixing tires

- Painting

Attachments

-

182.5 KB Views: 141

-

207.8 KB Views: 146

-

173.1 KB Views: 139

-

172.6 KB Views: 130

-

184.3 KB Views: 164

Last edited:

![Clap [clap] [clap]](https://www.theautomotiveindia.com/forums/images/smilies/Clap.gif)